Chinese Research Team's Breakthrough in High-Temperature Battery Separator Technology

In a significant development for the lithium battery industry, a research team in China has made a remarkable progress in enhancing the safety of lithium batteries. On November 10, the Institute of Modern Physics at the Chinese Academy of Sciences announced a major achievement in collaboration with Lanzhou University and the Advanced Energy Science and Technology Laboratory in Guangdong.

In a significant development for the lithium battery industry, a research team in China has made a remarkable progress in enhancing the safety of lithium batteries. On November 10, the Institute of Modern Physics at the Chinese Academy of Sciences announced a major achievement in collaboration with Lanzhou University and the Advanced Energy Science and Technology Laboratory in Guangdong.

The team has successfully developed a new process for preparing polyimide high-temperature separators using ion track technology at the Lanzhou Heavy Ion Accelerator. This innovation is set to address the long-standing safety concerns related to lithium batteries, especially the potential overheating during charging.

Separators are of crucial importance in lithium-ion batteries as they separate the positive and negative electrodes while allowing the conduction of lithium ions, which is essential for the battery's safe operation. Currently, commercial lithium-ion batteries have reached an energy density of up to 300 watt-hours per kilogram, but the pursuit of higher energy density has brought about safety challenges. Traditional polyolefin separators have poor thermal stability and uneven pore structures, leading to shrinkage at high temperatures, internal short circuits, and even thermal runaway.

Polyimide, on the other hand, stands out as an ideal material for high-temperature separators due to its excellent thermal stability, high mechanical strength, and good chemical stability. The research team's new process has yielded a polyimide separator with several outstanding features. It has a mechanical strength of 150.6 MPa, remarkable heat resistance with no shrinkage at 450°C, a narrow pore size distribution with a standard deviation less than 6%, and a vertically aligned pore structure with a curvature of 1.

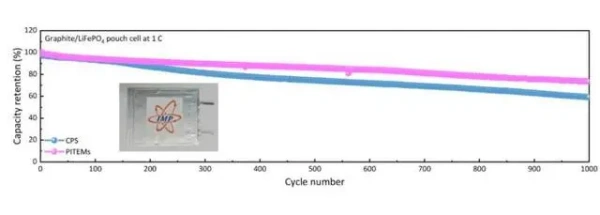

In tests, lithium/lithium symmetric cells using these polyimide high-temperature separators were able to cycle stably for 1200 hours at a current density of 3 mA/cm², with uniform lithium deposition on the metal electrodes, indicating a strong ability to suppress lithium dendrites. Additionally, soft-pack LiFePO4 batteries with these membranes could cycle stably for 1000 times at room temperature with a capacity retention rate of 73.25% and also exhibited excellent performance at an elevated temperature of up to 150°C.

This research breakthrough not only provides a new solution for the safety issues of lithium batteries but also paves the way for the development of more reliable and high-performance energy storage devices. It is a significant step forward in the field of lithium battery technology and is expected to have a profound impact on the future of the energy storage industry.